15/08/2023

To tackle emissions from the aviation industry, at present, Sustainable Aviation Fuel (SAF) is a frequently discussed and relied upon prospect. While research shows SAF is a ‘win’ in theory, there are questions over the supposedly ‘sustainable’ alternatives that are often overlooked.

The development and commercialisation of SAF will play a crucial role in carbon emissions reduction. However, this statement cannot be generalised for all different types of SAF. There are different SAF types utilising varied feedstock materials and production processes, and greater use of these fuels will not be free of negative environmental impact. SAF production, including changes in the way land is used, agricultural expansion and diversion of available fuels away from existing users, particularly the road transport industry, will all have a detrimental environmental influence.

To generate material wide-scale carbon reductions in flight, a considerable scale-up of truly environmentally friendly SAF is a necessity. However, at this point in time, feedstock availability is limited, and it will be difficult to support the required current and future demand of flights. IBA explains the feedstock availability challenge, the environmental impacts of SAF extraction and production and suggests viable long-term solutions.

The International Civil Aviation Authority (ICAO) defines SAF as an alternative aviation fuel that can “achieve net GHG emissions reduction on a life cycle basis; respect the areas of high importance for biodiversity, conservation and benefits for people from ecosystems, in accordance with international and national regulations; and contribute to local and social economic development, and competition with food and water should be avoided”.

Its role in reducing emissions should be accredited. However, the cultivation, harvesting, storage and transportation processes involved and the Indirect Land Use Change (ILUC) impacts during extraction and production of certain SAF feedstocks will result in GHG emission release and have detrimental environmental consequences. Increasing the use of biofuels may require an agricultural expansion globally which will intensify atmospheric carbon dioxide (CO2) concentrations. An expansion would mean the potential removal of rainforests and the destruction of these indispensable carbon sinks is illogical.

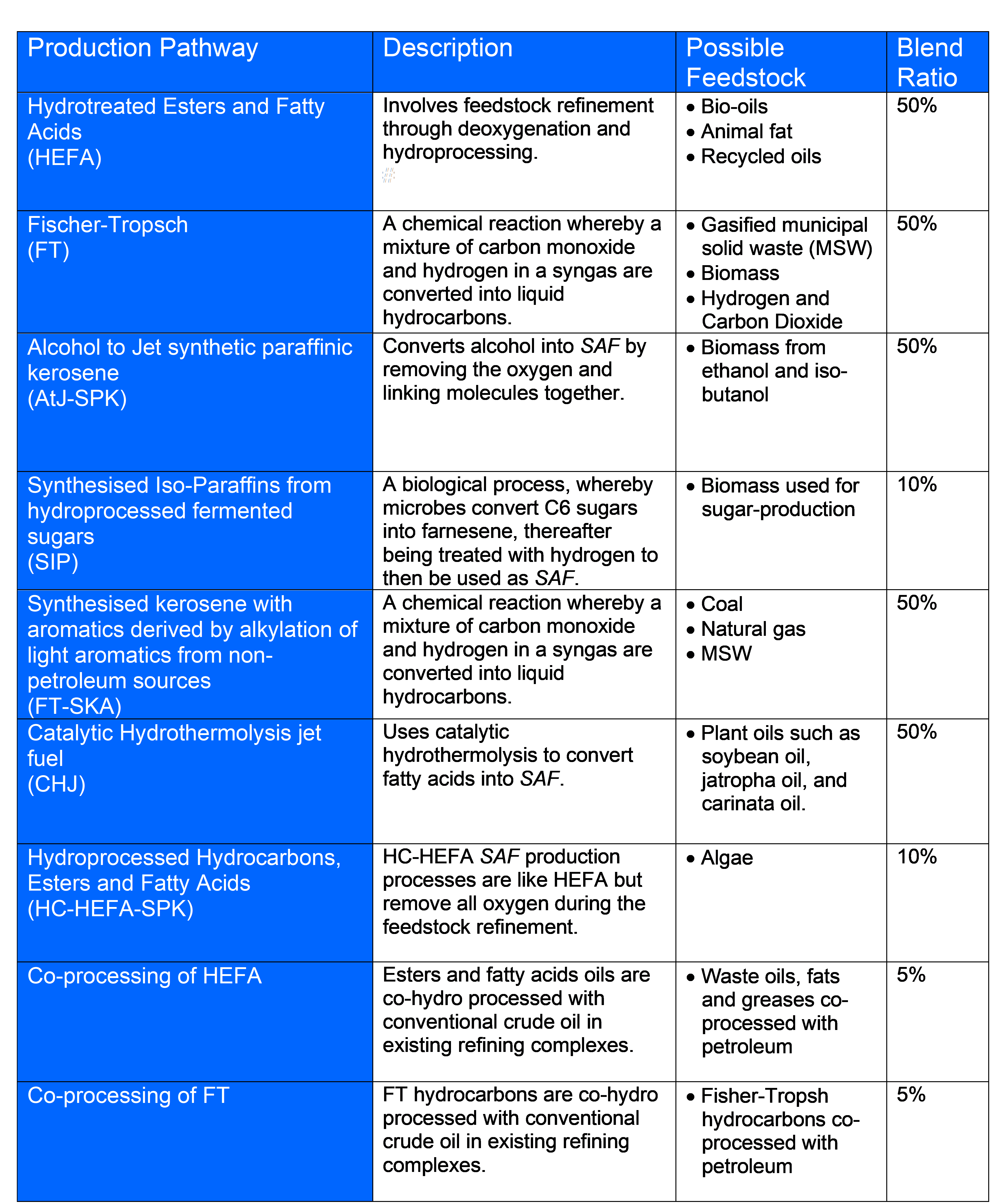

The American Society for Testing and Materials (ASTM) has approved nine SAF production pathways as of April 2023 and is evaluating eight more (See Table 1). Each uses conversion technologies to transform feedstocks into jet fuel, the various feedstocks include agricultural and forestry residue; algae, oil, seed, plants and energy grasses; fats, oils and greases from cooking waste and meat production; municipal solid waste and industrial carbon monoxide (CO) waste gas.

Table 1: SAF production pathways, process description, feedstocks for use and blend ratio

The only ASTM-certified pathway being used at scale currently is hydroprocessed esters and fatty acids (HEFA). Energy-intensive crop feedstocks have also recently been approved as HEFA feedstock. The necessary infrastructure for HEFA fuel production is already in place, therefore now and in the short-term HEFA fuels are likely to be relied upon because of their cost incentive. However, feedstock availability of waste fats, oils and greases (FOGs) is limited and, since SAF HEFA feedstocks are also used in road bio-fuel production, environmental groups argue that road transport should take precedence.

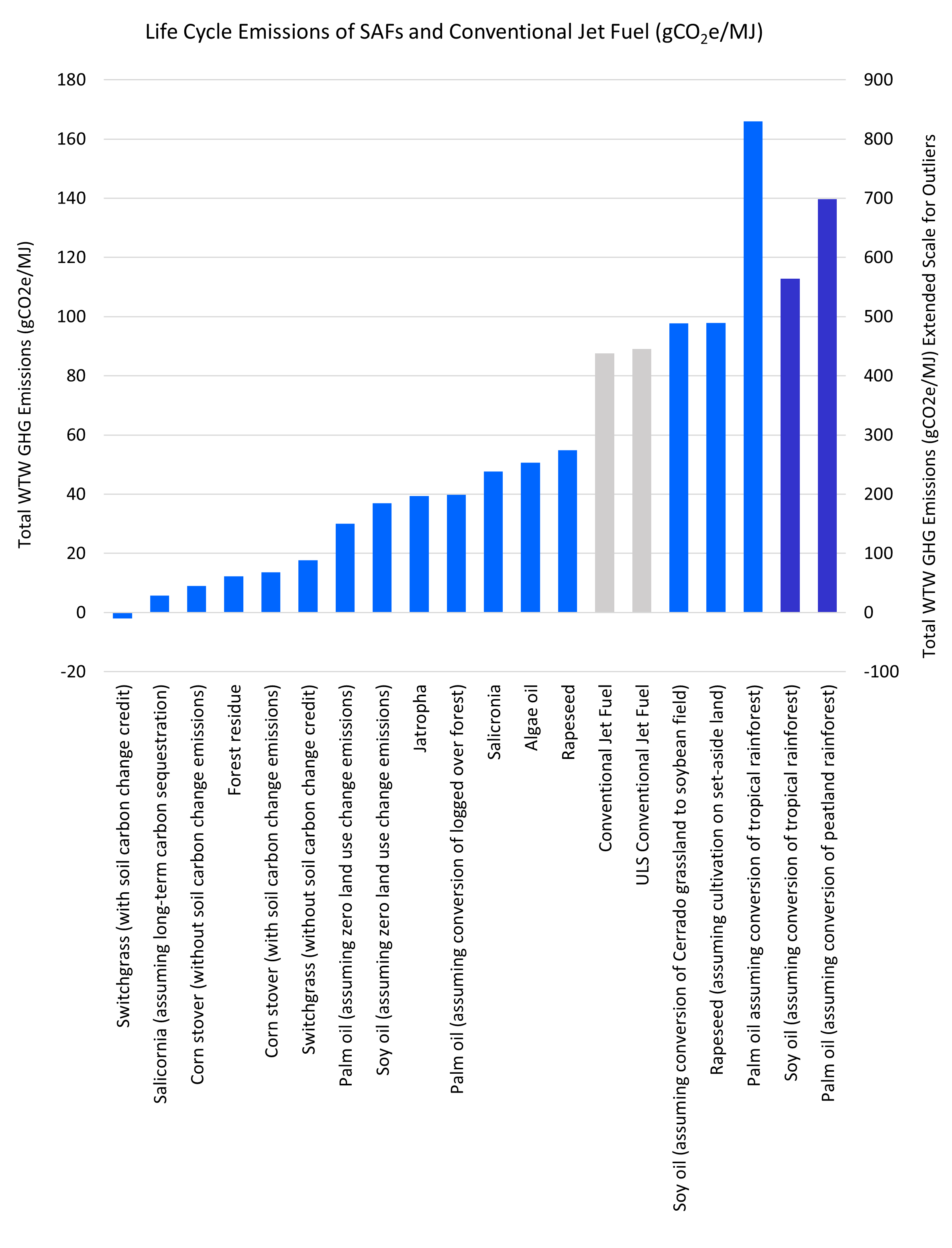

Providing there is an appropriate alternative, IBA would support a cap being imposed on aviation fuels using FOGs to avoid diverting feedstock from sectors already utilising HEFA fuel. Further, the recently approved crop feedstocks for HEFA create unfavourable land use impacts if land use conversion is required (as shown in the bar graph). SAF fraud is also a risk with low-cost plant oils passed off as waste oils, as in Asia recently where palm oil was being passed off as used cooking oil (UCO).

Graph 1: Total WTW GHG emissions (gCO2e/MJ) of conventional jet fuel, fuel from biomass and fuel from renewable oils.

*Data was extracted from ‘Life Cycle Greenhouse Gas Emissions from Alternative Jet Fuels’ by the Massachusetts Institute of Technology

This is the second most relied-upon production pathway due to its favourable energy density. Although, its high cost prevents a scalable production presently. To obtain the SAF produced from MSW feedstock, an external heating source is required for gasification. The process of incineration differs from the conventional combustion process used for landfill waste, making air pollution easier to control. This feedstock brings benefits as the volume of waste sent to landfill decreases, subsequently, methane emissions from landfills are reduced. Lastly, the by-products of gasification (e.g., glass) could have economic value as they are used in some construction processes.

There is limited research on the global availability of MSW for fuel. UK studies have estimated MSW could amount to 10% of the government’s net zero target by 2050. However, the UK is extremely reliant on imported feedstock and IBA urges caution and encourages further research into waste as a feedstock, to prevent excessive production should it consequently become in future a valuable commodity.

Additionally, PtL (power-to-liquid) SAF, or synthetic kerosene also known as eSAF, can be produced with FT technology; combining captured carbon with hydrogen made using renewable energy and water. If made using green hydrogen, PtL could be an economical and sustainable fuel to mitigate emissions in the aviation sector. Airbus and Rolls-Royce are developing promising aircraft with liquid hydrogen storage and combustion which could serve most short-haul and medium-range routes.

An emerging technology but feedstock production can involve adverse environmental consequences, including deforestation and biodiversity loss. These must be considered particularly since crop feedstocks compete with food production for land, water, and energy. Using edible food crops for SAF feedstocks can induce ILUC, and growing crops like corn in the volumes needed would use high amounts of water and fertiliser and could cause water shortages and eutrophication. Edible feedstocks like sugar and wheat often demand high levels of nutrients which environmental groups argue should be prioritised for consumption as opposed to fuel use. IBA is in favour of Europe’s prevention of crop-based ethanol used for AtJ, instead, ethanol must be waste-based, and supports this being adopted globally.

In April 2023, the European Parliament, the Council and the Commission finalised negotiations on the EU’s SAF law, known as ReFuelEU Aviation. The revisions put forward include:

Aviation fuel suppliers must provide a minimum share of SAF at EU airports, starting at 2% of overall fuel by 2025. By 2030 the share is 6%, by 2035 it’s 20% and by 2050 a maximum of 70%

Aircraft operators departing EU airports must refuel only with adequate fuel for the flight to avoid emissions resulting from unnecessary extra weight.

Airports must ensure they have sufficient infrastructure to support SAF fuelling.

It is a positive environmental step that the blending mandate excludes food and feed crops to support sustainability objectives, but precautions should go further. The cap IBA has already suggested on alternative fuels using FOGs could be imposed. Limiting the aviation sector’s monopoly over FOGs would prevent feedstock diversion from road transport and encourage investment in alternative SAFs, such as PtL.

The EU has addressed the challenges associated with land use change and GHG emissions in biofuel, bioliquid and biomass fuel production in all sectors. The directive sets national limits for high ILUC-risk fuels produced from food or feed crops that require significant expansion of land with high carbon stock. The significant drawback is that the limits do not apply to the aviation or maritime sectors, these industries are free to participate voluntarily. IBA suggests robust land conversion policies must be implemented globally if biomass-derived-SAF production is to increase significantly and such regulations must apply rigorously to the aviation industry. IBA welcomes the EU’s progress and its recent ban on imports of coffee, beef, soy, and other commodities if they are linked to deforestation but believes the exclusion should be extended to cover feedstocks for alternative fuels.

While the research suggests that some of the impacts associated with SAF production may be less consequential than the burning of conventional jet fuel, the environmental issues are being shifted elsewhere down the supply chain, commonly referred to as burden-shifting. Data on the life cycle GHG emissions of feedstocks for SAF is extremely limited, suggesting this is a subject area that needs further research. Available data regarding biofuels suggests that when considering direct and ILUC change for feedstock cultivation, the lifecycle GHG emissions for SAF can be higher than conventional jet fuel, especially for peatland and rainforest conversion as displayed in the bar graph1. To combat this concern, as aforementioned, policy implementation and refinement are necessary.

Currently, SAF costs approximately four times the price of conventional jet fuel and some airlines allocate a portion of a customer’s ticket value to purchase it; Finnair assigns 20 cents for example. Though future ticket prices are likely to be higher, studies suggest an economy ticket for a long-haul flight may increase by roughly $10-$17. IBA suggests that the cost burden for the airline and customer will be largely manageable.

Pending clearer understanding, alternative or supplementary mitigation strategies should urgently be addressed alongside SAF, including fleet improvements, flight route optimisation, ground emission mitigation, and carbon sequestration and offsetting. SAF technology cannot stand alone. Such steps will demand greater investment in the aviation sector and in emission mitigation technologies. To ensure uptake and manage appropriate feedstock use, it is imperative that policy and the guidance and support to meet targets is increased. If greater investment and improved technology can deliver SAF whose environmental benefits can be maintained as much as possible through all its lifecycle stages, its sustainable label will be justifiable.

Demand management is a desired but unlikely strategy to feature prominently in the approach towards achieving a net zero emissions target by 2050. IBA has conducted research and anticipates passenger air travel levels would need to be limited to approximately 25% above pre-pandemic levels. However, aviation growth is forecasted to rise above this level, despite the temporary reductions during the Covid-19 pandemic.

As PtL is in its infancy, limited research on lifecycle GHG emissions of hydrogen production and the various other processes involved in its manufacturing is available. If renewable energy supply and cost can scale as required and PtL production can divert away from grey to green hydrogen, it could emerge as a critical pathway. Its energy-intensive practices, lack of infrastructure and nascent carbon capture technologies make it expensive currently. However, IBA predict that by mid-century this pathway will be the most competitive due to its scalability and the increased abundance of renewable energy. IBA anticipates airlines may also benefit from a more stable PtL SAF supply due to the ability of nations to benefit from independent production protected from the volatility of geopolitics surrounding fossil fuels.

Further research is needed into the life cycle GHG emissions of feedstocks for SAF, specifically comparative data of SAF and conventional jet fuel. The environmental impacts of SAF and a future scale-up of production to meet increasing demand is difficult to assess accurately. While some impacts associated with SAF production may be less harmful than burning conventional jet fuel, the environmental issues are being shifted elsewhere rather than being eliminated.

Until research clarifies an accurate comparative emissions picture for jet fuel and SAF, IBA questions whether a more appropriate label would be ‘alternative’ fuels rather than sustainable. The industry has a long way to go before it can confirm that SAF deserves its sustainable classification.

IBA are leading the aviation emissions agenda with a dedicated ESG Consulting team and IBA NetZero, Winner of the Aviation 100 Sustainability Technology Award for 2022 & 2023.

Glossary

AtJ: Alcohol-to-Jet

eSAF: Synthetic kerosene

FOGs: Fats, oils (such as used cooking oil – UCO) and greases

FT: Fischer-Tropsch

GHG: Greenhouse Gas

Green and grey hydrogen: Hydrogen can be produced from a range of resources including fossil fuels, nuclear energy, biomass and renewable energy sources. Green (or clean) hydrogen is produced by using energy from renewable energy sources like solar or wind power. Grey hydrogen is the most common and is generated from methane.

HEFA: Hydrotreated esters and fatty acids

ILUC: Indirect Land Use Change. The unintended consequence of releasing more carbon emissions due to land use changes around the world following the expansion of croplands for ethanol or biodiesel.

MSW: municipal solid waste

PtL: Power-to-liquid SAF or synthetic kerosene also known as eSAF

SAF: Sustainable Aviation Fuel