03/10/2023

As the world looks towards revolutionary forms of air travel, electric vertical take-off and landing (eVTOL) vehicles seem to be the main talking point in the realm of futuristic transportation and aviation.

eVTOLs are expected to revolutionise the skies and their potential applications are positioned to shift urban mobility while opening new market horizons. In global cities prone to congestion, such as New York, Shanghai, and London, they can serve as an efficient form of alternative transportation in these environments. Similarly, where light helicopters have previously been the market standard, eVTOLs are being positioned as viable replacements for existing, ageing fleets.

Analysis from IBA Insight shows that total eVTOL orders have reached approximately 7,487, with 4,050 on backlog. The success of this new technology lies in its viable use across several sectors including logistics transport, search and rescue, emergency medical services, offshore, and servicing wind farms.

The opportunity to deliver a quieter, cost-effective solution with fewer emissions is also driving a new “space race” – where participants range from established leaders to new industry players, of all sizes. However, gradual change in market ownership is expected over the long term through mergers and acquisitions - especially as smaller players come together or are consolidated into larger OEMs.

But despite the growing enthusiasm and optimism surrounding eVTOLs, it is essential not to overlook the significance of battery technology in making these aircraft viable and practical. The role of lithium specifically, is the cornerstone that supports the entire eVTOL industry, and lithium-based batteries, notably lithium-ion batteries, are at the forefront of powering these cutting-edge vehicles.

Lithium-ion batteries are known for their high energy density, which is one of the driving factors for their widespread adoption across a range of applications including electric vehicles, consumer electronics, and solar power storage.

Energy density refers to the amount of energy that a battery can store per unit of its weight or volume. The high energy density of lithium-ion batteries means that eVTOLs can store a significant amount of electrical charge, therefore providing them with adequate flight ranges and reducing the need for frequent recharging.

In the eVTOL world, range is everything especially where it looks to compete between helicopters and ground transport. So, the need to improve lithium-ion batteries is paramount, as longer ranges increase the capability and efficiency of eVTOL functions. As research and development continue, a continuous effort is being made to improve the energy density of lithium-ion batteries even further.

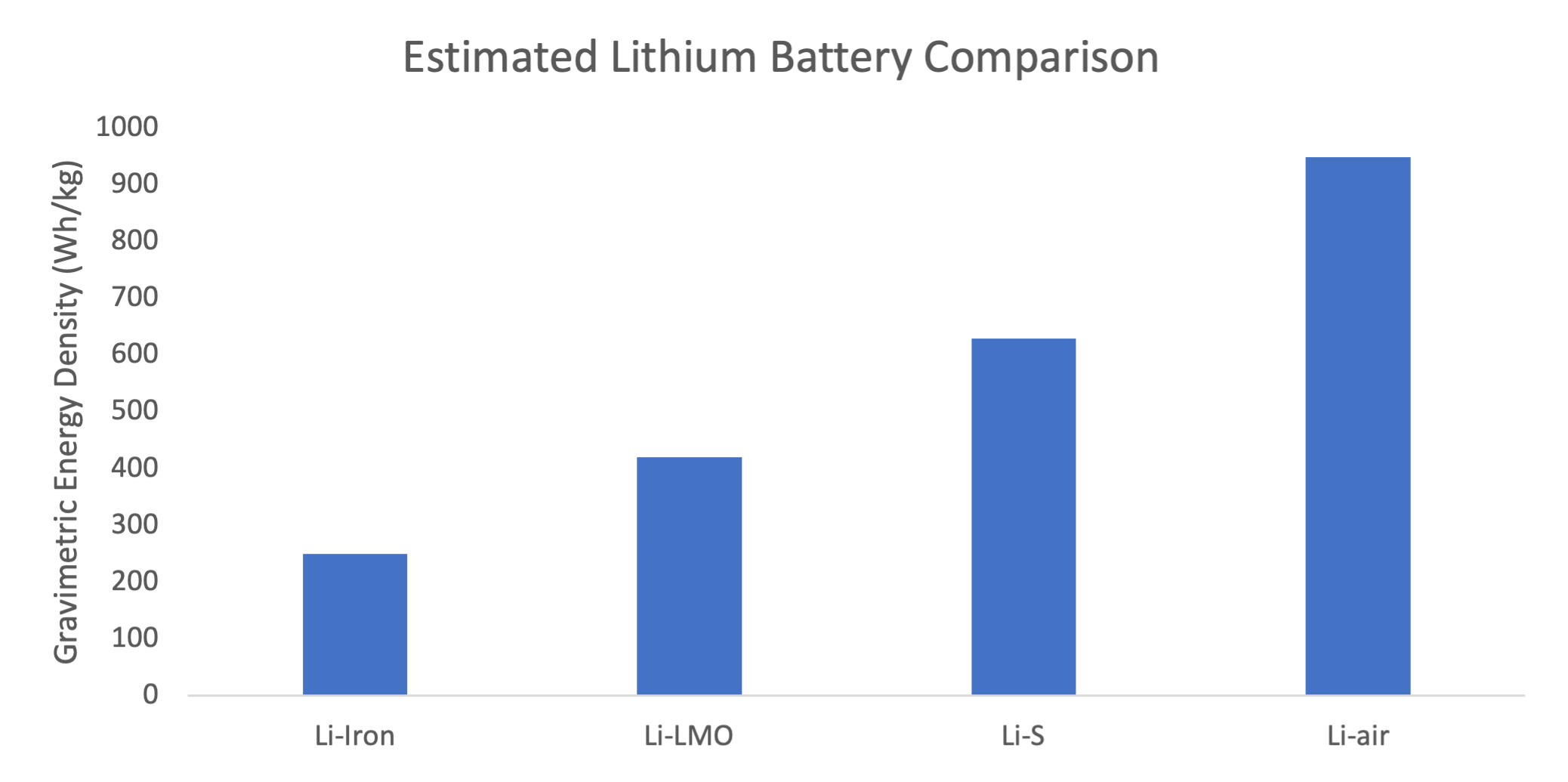

However, it is also becoming more evident that lithium-ion may not be the only option. Potential candidates for powering eVTOLs include various alternative forms of lithium, such as lithium-sulfur, and lithium-air batteries. Research and trials into emerging forms of lithium technology show promise in satisfying the growing requirement for increased flight ranges and efficiency.

Source: The Faraday Institution

Lithium-sulphur and lithium-air alternatives both have the potential for higher energy densities, which could help the longer-range requirements for some eVTOLs. These technologies could also contribute to the development of lighter-weight batteries, which would ultimately help improve efficiency, manoeuvrability, noise reduction, and overall safety of eVTOLs.

Lithium sulphur is a type of rechargeable battery, and its cells replace the metal-rich cathode of lithium-ion cells with cheaper and more abundant elemental sulphur. Further research is still needed, where advancements in sulphur cathode materials, electrolyte design, and battery cell architecture have the capabilities to accelerate lithium-sulphur batteries in the future. Lithium-air batteries have a more complex chemistry that uses oxygen to oxidise a lithium-metal anode. So far Lithium-air batteries have been largely limited to a pure oxygen environment (Li-O2) and have a limited cycle life due to side reactions involving the cathode, anode, and electrolyte.

There is also a lot of investment in solid-state batteries (SSB), representing a transition from conventional lithium-ion batteries. The limitations of traditional lithium-ion batteries are well documented, including issues with ageing, transportation, cycle life, charging time, temperature performance, and costs. So, researchers have focused their attention to solid-state batteries. Lithium-ion batteries are composed of liquid electrolytes, whereas solid-state batteries use solid electrolytes. This fundamental differentiation in components helps eradicate flammability and safety concerns.

Furthermore, solid-state batteries adopt metallic lithium anodes, allowing for higher specific capacities, thus achieving heightened energy densities and prolonged energy storage capabilities. This radical advancement in battery design has spurred efforts to bring solid-state batteries to widespread commercial use, offering the prospect of a transformative and sustainable energy landscape in the near future. SSBs are already being used in smaller-sized commercial applications such as watches and medical devices.

As manufacturers and developers take to the skies, battery technology is playing a crucial role in both the development and success of eVTOL aircraft. There has been a surge in funding and investment towards battery technology, as the need for storage solutions surges.

More than just capacity, the effectiveness of battery technology also creates other implications for the eVTOL market. According to IBA Insight new values of eVTOL aircraft will sit between US$ 2-4 million, and battery life is a key determinant of this. Among the primary operating costs for an aircraft, battery costs determined by stored energy density contribute heavily to the manufacturing costs.

Furthermore, the challenges of sourcing raw materials, recharge time between flights and our predicted economic life of 1-2 years per battery need significant consideration for operational efficiency.

IBA Group is leading the aviation emissions agenda with a dedicated ESG consulting team backed by our IBA NetZero platform, winner of the Aviation 100 Sustainability Technology Award for 2022 & 2023. Our award-winning Valuations team are also experienced in providing asset modelling and forward depreciation trends for general and emerging aviation aircraft.

Related content